MATERIALS TESTING SERVICES

Plate Bearing Test

Optimise Your Construction Project with Premier CBR Testing Service

The CBR test measures the pressure required to penetrate the soil with a standard circular piston and then compares this to the penetration of a standard material (usually crushed rock).

The ratio of the resistance of the soil to the standard material is the CBR.

Use the form below to get in touch with MTS and one of the friendly team will get straight back to you.

Exploring CBR Testing Services

MTS, boasting more than 20 years of testing in Ireland, apply their expertise to a wide range of projects, from a basic site test to intricate civil engineering tasks.

Now, how is CBR applied onsite?

The most common way to determine the CBR in the field is to perform plate bearing tests. In this process, a steel plate (ranging from 300 to 750mm in diameter) is placed on the surface of the subgrade soil, and then (various loads applied using a hydraulic jack with the resulting settlement recorded at regular intervals).

The deformation of the soil is then measured at the centre of the plate, and the results are used to calculate the CBR value.

The plate bearing test is an effective way to determine the in-situ strength of the soil. It allows engineers to evaluate the suitability of the subgrade for the proposed design loads, which can help in determining the required pavement thickness and reinforcement.

Plate Bearing Test

1. Site Preparation: The site is prepared by removing any vegetation, debris, or loose soil from the area where the test will be conducted. The subgrade should be compacted to the required density and moisture content.

2. Test Procedure: The plate bearing test is performed by placing the steel plate on the subgrade and loading it with weights or hydraulic jacks. The deformation of the soil under the plate is then measured using a dial gauge or laser displacement transducer.

3. Data Analysis: The test data is used to calculate the CBR value for the soil. An approximate empirical correlation with CBR can be made using the modulus of sub-grade reaction.

Key Takeaways

CBR testing is essential for assessing soil stability and strength for construction projects, ensuring that infrastructure such as roads and buildings have adequate foundations.

MTS provides Professional CBR testing services throughout Ireland, providing uniform rates for laboratory and on-site tests, utilizing precise equipment and standardized methods to ensure accuracy.

Technicians play a crucial role in the CBR testing process, from sample preparation to interpreting results, ensuring adherence to standards, and enabling informed decision-making for construction design and planning.

The Essentials of California Bearing Ratio (CBR)

It’s essential to note that the results of the plate bearing test should be used in conjunction with other site investigation data, such as soil classification, moisture content, and density. The data gathered from these tests can then be used to design pavements that are both cost-effective and durable.

CBR <3% is considered unsuitable and requires strengthening using Geo-Grids or the addition of capping material, CBR >3% is considered suitable for formation level, CBR>15% considered suitable for capping & CBR>30% considered suitable for Sub-base material.

Now that we’ve discussed the services, it’s time to examine the fundamental nature of the California Bearing Ratio (CBR) test, also known as the California Bearing Ratio Test. Initially developed by the California State Highway Department, the CBR test is a significant tool for assessing the strength of subgrade soils.

The CBR test plays a vital role in determining the design and required material thickness for highways, airport runways, and parking lots by assessing soil stability and strength. The method involves:

- Measuring the pressure needed for a plunger to penetrate soil

- Comparing it to the pressure required on a standard reference material

- Calculating the load-bearing capacity of subbases and subgrades.

These CBR values are then used by geotechnical engineers to:

- Compare the soil strength with a well-graded crushed stone

- Inform decisions on pavement layer thickness

- Understand the subgrade’s suitability for supporting construction.

In-Depth Analysis: Laboratory CBR Testing

Laboratory CBR testing adheres to a standardized method. This involves using measured pressure to penetrate a soil sample with a plunger and comparing it to the pressure needed for the same penetration in standard crushed rock material.

The process is meticulous and requires an equal penetration rate of 0.05 inches per minute. The loads at specific penetration depths are recorded up to 0.500 inches. These CBR values indicate the strength of the soil, with high values denoting harder surfaces. The calculation involves dividing corrected stress values from penetration depths by standard stresses.

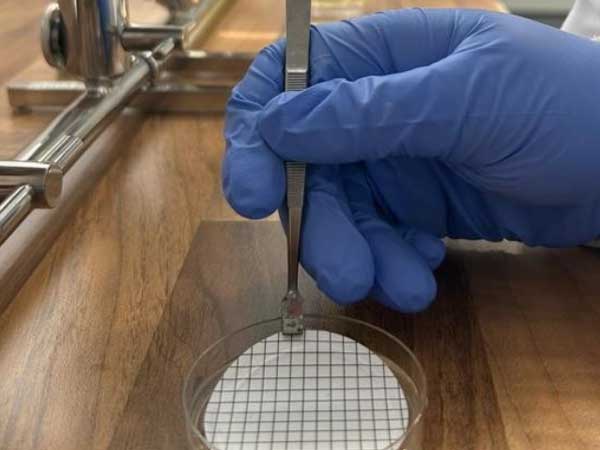

Proper preparation of soil samples is an integral part of laboratory CBR testing. Technicians need to follow standardized methods to ensure accuracy and consistency.

The CBR test specimens can be soaked to simulate adverse moisture conditions like rainfall or flooding. This generally involves a 96-hour submersion with a surcharge load to replicate pavement weight. This soaking phase is an essential step for making informed decisions in material selection for construction projects.

Precision Equipment Used in CBR Testing

Precision is key in CBR testing, and that’s where the role of specialized equipment comes into play. Tools such as:

- Dial gauges

- Spacer discs

- Surcharge weights

- Loading machines

are used, all adhering to international standards like BS 1377, EN13286-47.

These machines, like the Triplex Multi-tester utilizing a DBBSM-50kN Load cell and an IDR4XY dual channel transducer indicator system., come with a motorized twin-column frame to ensure consistent testing. They are designed to suit a variety of laboratory environments. Additional tools such as CBR Surcharge Weights, both annular and slotted, and Spacer Discs help to configure the sample size and add necessary weight during the test.

The precision in CBR testing is further maintained with tools like a 0.001in penetration dial indicator and displacement transducers, which are essential for conducting an accurate penetration test. These tools offer precise penetration and displacement measurements.

Calculating CBR Values: A Step-by-Step Guide

Calculating CBR values involves a series of steps:

- Specimen preparation

- Compaction

- Measuring swell percentage after soaking

- Performing the load test to gather load versus penetration data.

The CBR value is determined by measuring the load required for the piston to achieve specific penetrations, and then comparing this pressure to that of standard crushed stone material. A graph plotting dry density versus corresponding CBR values for each sample is used to find the CBR value for a specified dry density, aiding in the design process.

Interpreting Test Results for Project Success

Interpretation of CBR test results is a key stage in the process. Technicians calculate CBR test results by plotting a stress versus penetration curve and determining the stress for penetrations at 0.1 inch and 0.2 inch. These measurements reflect the soil’s resistance compared to a standard crushed stone at those penetration levels.

The role of technicians is critical in comparing the obtained values with established standards for different soil types and construction projects. This ensures the validity of the results and adherence to UK building standards. By employing professional CBR testing services, project accuracy and efficiency are enhanced, providing essential data for material selection and foundation design.

Comparing CBR and Plate Load Tests

Although CBR testing is crucial, the construction industry utilizes a variety of other testing methods as well. The Plate Load Test is another commonly used test, particularly for soils with larger particles or harder textures.

The Plate Load Test involves sequentially applying load and measuring settlement with heavy machinery, whereas the CBR test uses a standardized plunger on a smaller scale. A Plate Load Test requires excavation to create a pit, with specific dimensions relative to the diameter of the test plate, before placing the plate and applying load to gauge settlement and determine safe loading capacity.

Despite the differences, both tests provide valuable soil strength and bearing capacity assessments. In fact, Plate Load Tests can offer a fairly accurate CBR equivalent value, derived from the reaction load and modulus of subgrade reaction, which is crucial for road design.

Ensuring Quality: The Role of Technicians in CBR Testing

The CBR testing process heavily depends on the skills and expertise of technicians. They are responsible for conducting a variety of tests, ensuring each one is performed to specific standards with precision and accuracy.

These skilled professionals are responsible for maintaining calibrated testing equipment, recording detailed test data, and interpreting load-penetration curves. Their expertise significantly contributes to reliable decision-making and adherence to standards without the need for other testing apparatus.

The Impact of Soil Properties on Construction Projects

Construction projects are greatly influenced by the properties of soil. They dictate the design and strength of foundations and the superstructure they support, enabling the calculation of load capacity and bearing pressures. Poorly analyzed soil properties can lead to catastrophic structural failures such as ground collapse or subsidence. Hence, comprehensive soil studies are vital before initiating any construction project. By accurately determining the bearing capacity, CBR testing can guide the appropriate selection and optimization of pavement materials, potentially reducing overall costs.

On-site dynamic CBR testing measures the bearing ratio of undisturbed soil samples in the field, providing a robust representation of the soil’s bearing value. This is critical in making informed decisions about construction planning, especially when considering the capacity to bear road subgrades and base courses.

Maximizing Project Efficiency with Professional CBR Testing

The efficiency of a project can be maximized through professional CBR testing. A trained single operator can perform 8-10 PBT tests in a day, assuming surface preparation is complete.

The provision of immediate CBR test results on-site offers several benefits:

- Expedites the decision-making process during construction

- Enhances efficiency

- Reduces potential delays in construction projects

- Contributes to successful and timely project completion.

Summary

CBR is an important concept in pavement design and construction. It is used to determine the strength of the subgrade soil, which is a critical component in the design of any pavement system. The plate bearing test is an effective way to determine the CBR value in the field, providing engineers with essential data for making design decisions.

The role of technicians in ensuring the accuracy and consistency of PBT testing cannot be overstated. Their expertise contributes significantly to the reliability of decision-making processes and adherence to standards. In conclusion, incorporating professional CBR testing into construction projects not only maximizes efficiency but also reduces potential delays, contributing to successful and timely project completion.

Frequently Asked Questions

What does CBR 5% mean?

CBR 5% is the ratio, expressed as a percentage, of the force required to penetrate a soil mass with a standard plunger to that required for the same penetration in the standard material. This ratio is typically determined for penetrations of 2.5 mm and 5 mm.

What is CBR testing?

CBR testing is a method used to evaluate the strength of subgrade soils, particularly important for construction planning.

How is a CBR test conducted?

A CBR test is conducted by measuring the pressure needed for a plunger to penetrate soil and comparing it to a standard reference material, which helps in calculating load-bearing capacity.

What is the role of technicians in CBR testing?

Technicians play a pivotal role in CBR testing by conducting tests, ensuring precision, maintaining equipment, recording detailed data, and interpreting load-penetration curves.

How does soil impact construction projects?

Soil significantly influences the design and strength of foundations in construction projects. Comprehensive soil studies are vital for ensuring the success of the project.

Destructive Weld Testing

Water Sampling

19 Kernanstown Ind. Estate

Carlow

R93 PY67

Ireland

+353 59 913 0044

info@mtsltd.ie